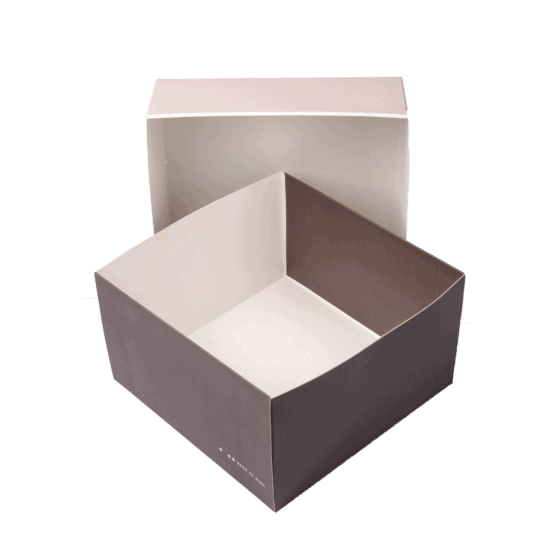

Paper boxes

We believe that even such a banal thing as a paper box deserves attention. With us, you can design them yourself and we will hand over the already finished product to you. There is also the option of custom printing, for example, with your logo, so you can perfectly combine advertising purposes with a product that will serve you well.

-

design as desired

-

FREE GRAPHICS PREPARATION

-

CUSTOM PRODUCTION FROM 5,000 PCS

DETAILS

Details make quality

Are you looking for someone to turn your ideas into reality? We are forged in that! Together, we will choose the size and shape of the boxes based on their primary purpose and introduce you the details that will make the final product unique.

We also have our own graphic studio, so we will be happy to design graphics for you completely free of charge.

Materials

Wood biomass is the main raw material in paper production, while 2 to 3 tonnes of wood is usually needed to produce one tonne of paper. Approximately 80,000 sheets of A4 office paper are produced from a single tree. The paper is very recyclable. It offers countless adjustments, weights (g / m2) and surfaces. It can be varnished, coated with plastic, laminated, painted, etc. The first mentions of paper production are from the Chinese Tang dynasty (618 - 907 AD), they used it in the preparation of tea or as toilet paper. The first paper bag machine was introduced in 1868 by the American inventor Margaret Knight.

The basic idea of the non-governmental non-profit organization Forest Stewardship Council (FSC) is to support environmentally friendly, socially beneficial and economically viable forest management and thus paper production. In this way, it helps to protect the world's endangered and devastated forests.

The FSC has created a prestigious international certification system for forests and companies that process wood from certified forests into products, especially paper.

The FSC logo on the product is a guarantee that your purchase supports forestry and careful paper production. The product marked in this way is respectful of nature and local people.

The FSC has created a prestigious international certification system for forests and companies that process wood from certified forests into products, especially paper.

The FSC logo on the product is a guarantee that your purchase supports forestry and careful paper production. The product marked in this way is respectful of nature and local people.

Cardboard is a single or multi-layer hard paper weighing more than 150 g/m2. Terminologically correct designation for cardboard is plain cardboard. In the category of consumer packaging, the so-called folding cartons form a very important group. Packaging is highly environmentally friendly because it is fully recyclable. Foldable cardboard is a multi-layer material and the composition of the individual layers is different. It is produced in weights of 200-650 g/m. They are most often printed in a four-color version. Different types of surface treatment are possible, namely printing and partial varnish, UV varnish or lamination. The packaging can be supplemented with variously shaped cut-outs, windows, holes for hanging, tear perforations and additional fixation inserts to secure the goods in the packaging. Simple cardboard and cardboard with a coated surface are mainly used for the production of foldable carton packaging. They differ from each other by the type of pulp and the composition of the individual layers, which is reflected in the technical parameters of the cardboard and its price. The choice of the type of cardboard therefore depends mainly on the end use of the packaging and the requirements for its printing.

Corrugated cardboard is a cardboard made of one or more layers of corrugated paper that is glued between multiple layers of another paper or cardboard. Its advantages include edge strength, surface compressive strength, compressive strength and thickness. This makes it an ideal packaging material for fragile, expensive goods, such as filling and more.

Corrugated cardboard is a cardboard made of one or more layers of corrugated paper that is glued between multiple layers of another paper or cardboard. Its advantages include edge strength, surface compressive strength, compressive strength and thickness. This makes it an ideal packaging material for fragile, expensive goods, such as filling and more.

Materials

Our work

Christmas stamp box

Paper box for cookies

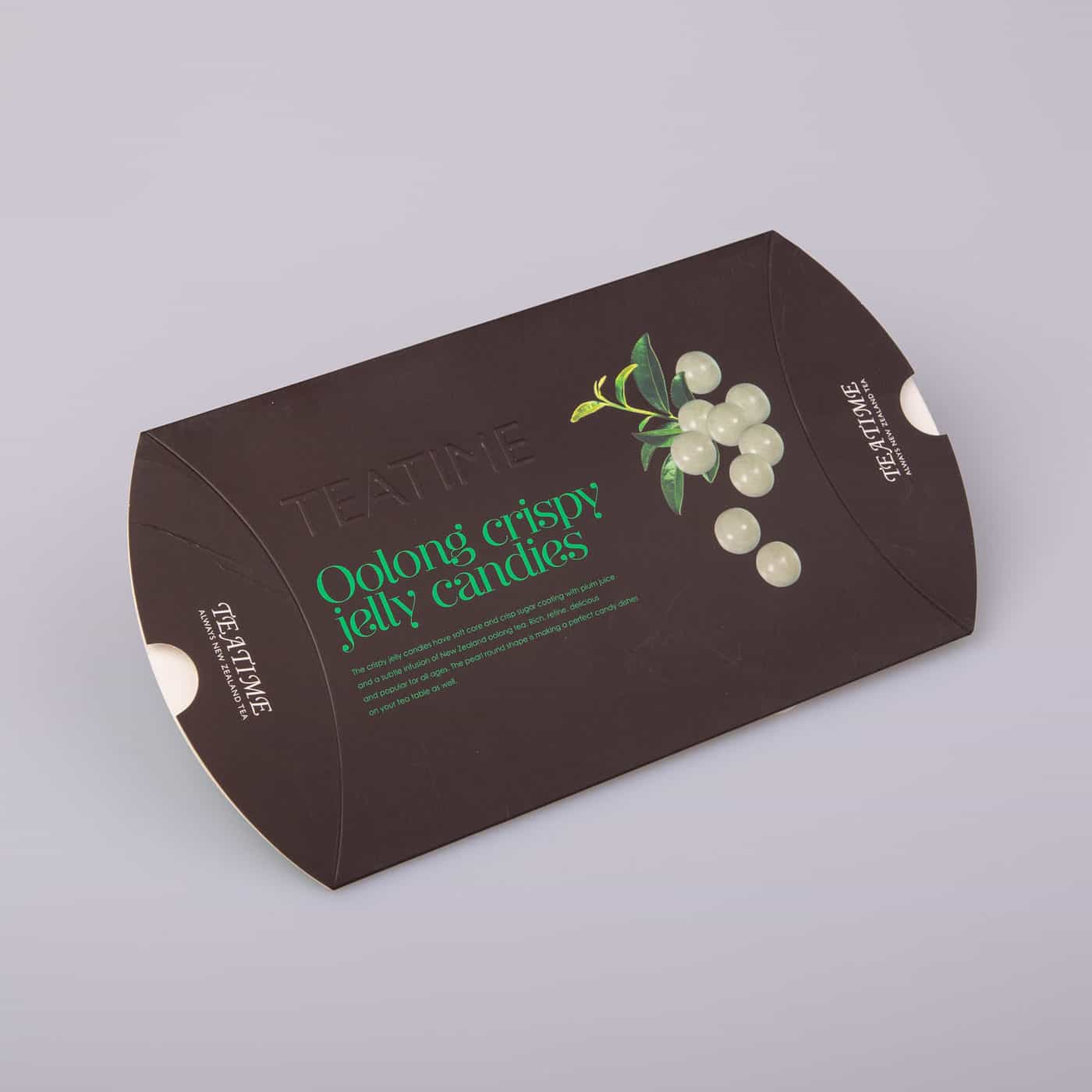

Foldable paper box for sweets

Small paper box

Luxury jewelry box

Paper box for Christmas cutters

Paper box

Luxury gift box for mineral water

Luxury gift box for jewelry

Set of gift boxes with ribbon

Luxury paper case for glasses

Luxury paper tea box

Christmas gift paper box

Luxury tea box

Folding cardboard box with plastic handle

Cardboard box with ribbon

Luxury paper jewelry box

Paper buckle

Cardboard box with window

Paper buckle

Natural paper tube

Paper tube with metal lid

Round paper box

Foldable cardboard box

Paper tube for glasses

Oval natural paper tube

Foldable gift box with cover

Paper tube for vinegar

Cardboard box

Paper envelope with adhesive strip

Are we what you are looking for?

We have a patent for bringing blue from the sky. Thanks to a strong, long-term position on the market, we have experience and technologies that can cover any requirements. We are a family business and we build our business on healthy values.

Why SALE

why SALE