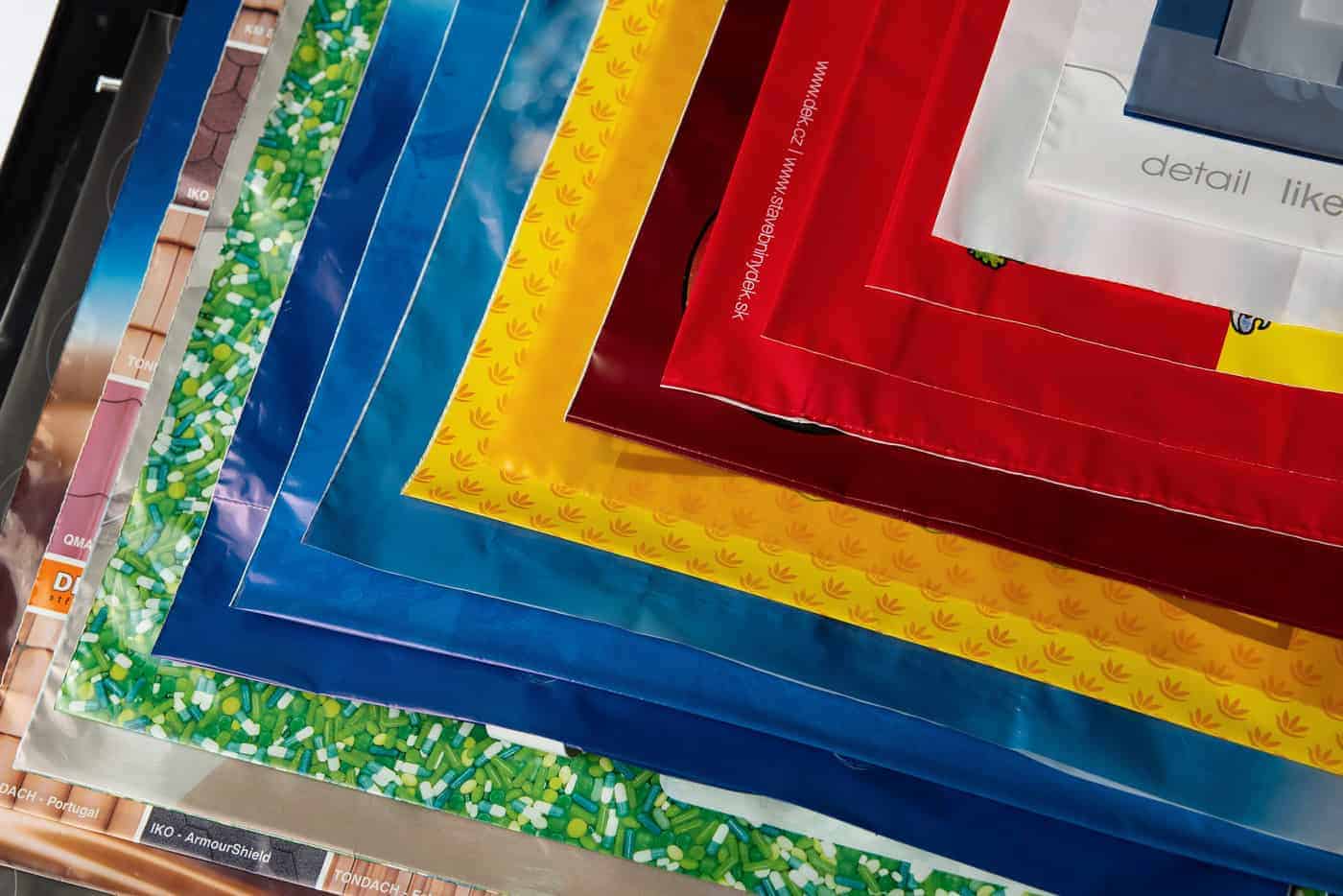

Plastic envelopes and zip-lock bags

You can please customers with the package before unpacking it. How? After all, by a tasteful and pleasing bag or envelope! The sum of ornate details forms a perfect complex. And the details that make up the customer's first impression are the most important.

-

Suitable for e-shops

-

Free graphics preparation

-

CUSTOM MANUFACTURING FROM 5,000 PCS

DETAILS

Details make quality

The first impression is important. That is why we will be happy to produce bags and envelopes for packaging your products so that the customer cheers even before unpacking the package.

Need to pack what fits into your palm? Or will it be a proper package? We will adjust the size according to your needs, it’s entirely up to you. We will advise you on choosing the right material. You can also choose from matte variants. The overall look will be decorated with a print, which we will prepare for you to order.

The resulting product will be bags and envelopes with an adhesive strip, which will simply excite you.

Materials

LDPE or low density polyethylene, colloquially called plastic, is the most widely used plastic in the production of packaging. Its property can be corrected by various additives: strength or shrinkage. It can be used for a whole range of packaging. We use it for the production of common carrier bags, bags for industrial production, bags, e-commerce bags with adhesive strip, boundary tapes. For e-commerce bags, we recommend the so-called BI-LDPE, a two-layer foil - white on the surface, black inside, which prevents the contents inside the bag from shining through. LDPE foil is odorless and tasteless. The foil can be colored, but today full-area printing is preferred. Heat resistance is from -50 °C to +85 °C. Clear foil is suitable for contact with food. Products can be recycled or disposed of by incineration. The recommended thickness of conventional bags is about 50 microns.

High density polyethylene (HDPE) is a thermoplastic invented in 1957. HDPE foil has been produced in Czechoslovakia since 1976 under the Mikroten brand, which has become synonymous for HDPE. HDPE bags and sacks are among the cheapest packaging materials. They are well recyclable, storable and suitable for contact with food. 15-20 micron foil is usually used for the production of bags. Foils with thicker thickness can be used for the production of luxury bags.

Biaxially oriented polypropylene film (BOPP) is widely used, for example, in food packaging (especially pastries and sweets), boxes (CDs, tea, coffee), perfumes, magazines, textiles, books, etc. The foil is most often used for packaging on packaging or folding machines. It is strong with optimal breathability, resistant to temperature fluctuations and humidity, suitable for contact with food with high weld strength. Transparent color allows visual inspection of packaged goods, it is very easy to print even with demanding prints.

PLA (polymlečná kyselina) je biologicky plně odbouratelný materiál, vyrobený z kukuřičného nebo bramborového škrobu.

Tento certifikovaný materiál vyrobený z kukuřičného granulátu je 100% kompostovatelný v průmyslových kompostárnách a splňuje tak evropskou normu EN 13432.

Výrobky, které je možné z tohoto materiálu vyrobit: sáčky a pytlíky s nebo bez zipu, tašky s průhmatem, tašky košilky, e-commerce obálky s lepící lištou

Tento certifikovaný materiál vyrobený z kukuřičného granulátu je 100% kompostovatelný v průmyslových kompostárnách a splňuje tak evropskou normu EN 13432.

Výrobky, které je možné z tohoto materiálu vyrobit: sáčky a pytlíky s nebo bez zipu, tašky s průhmatem, tašky košilky, e-commerce obálky s lepící lištou

Materials

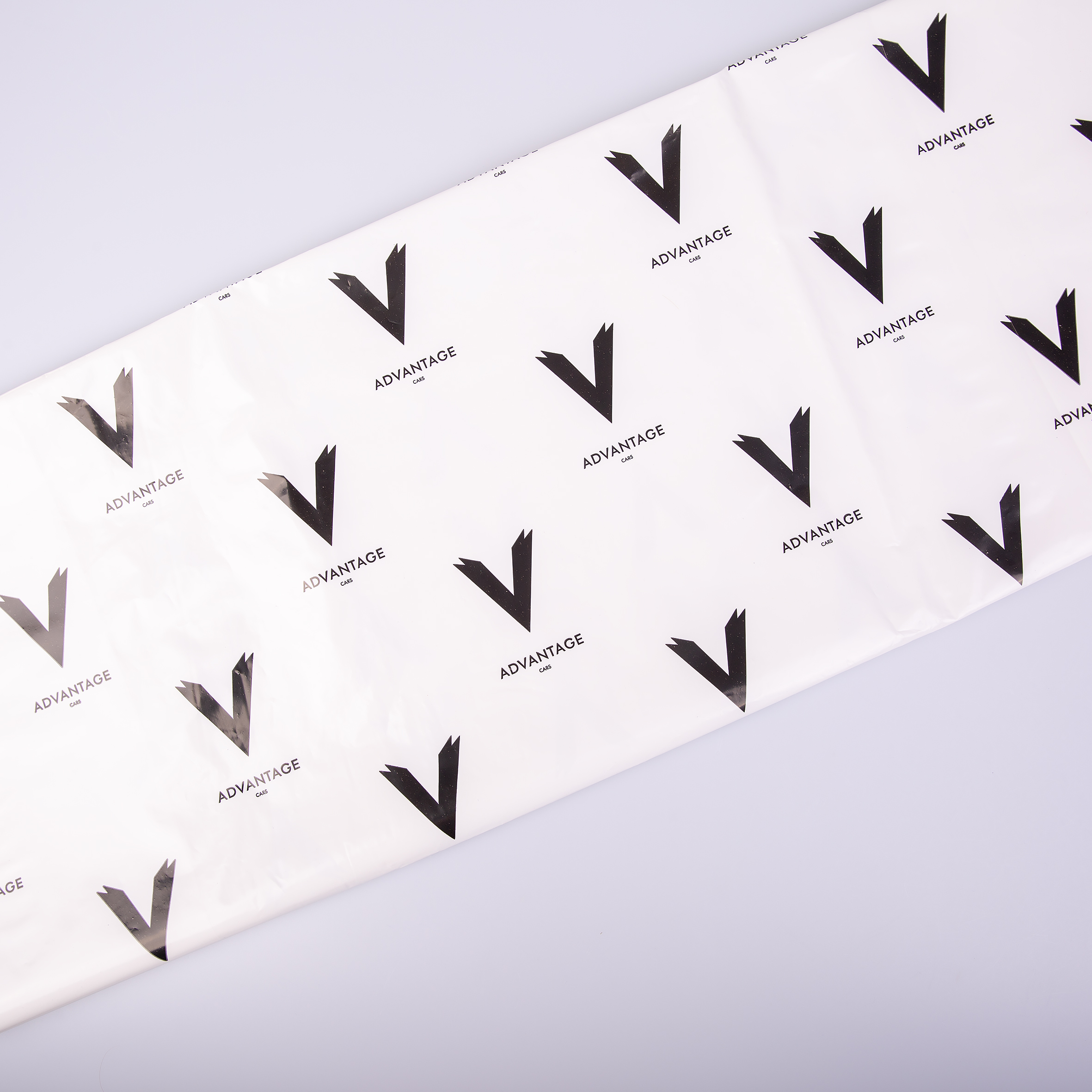

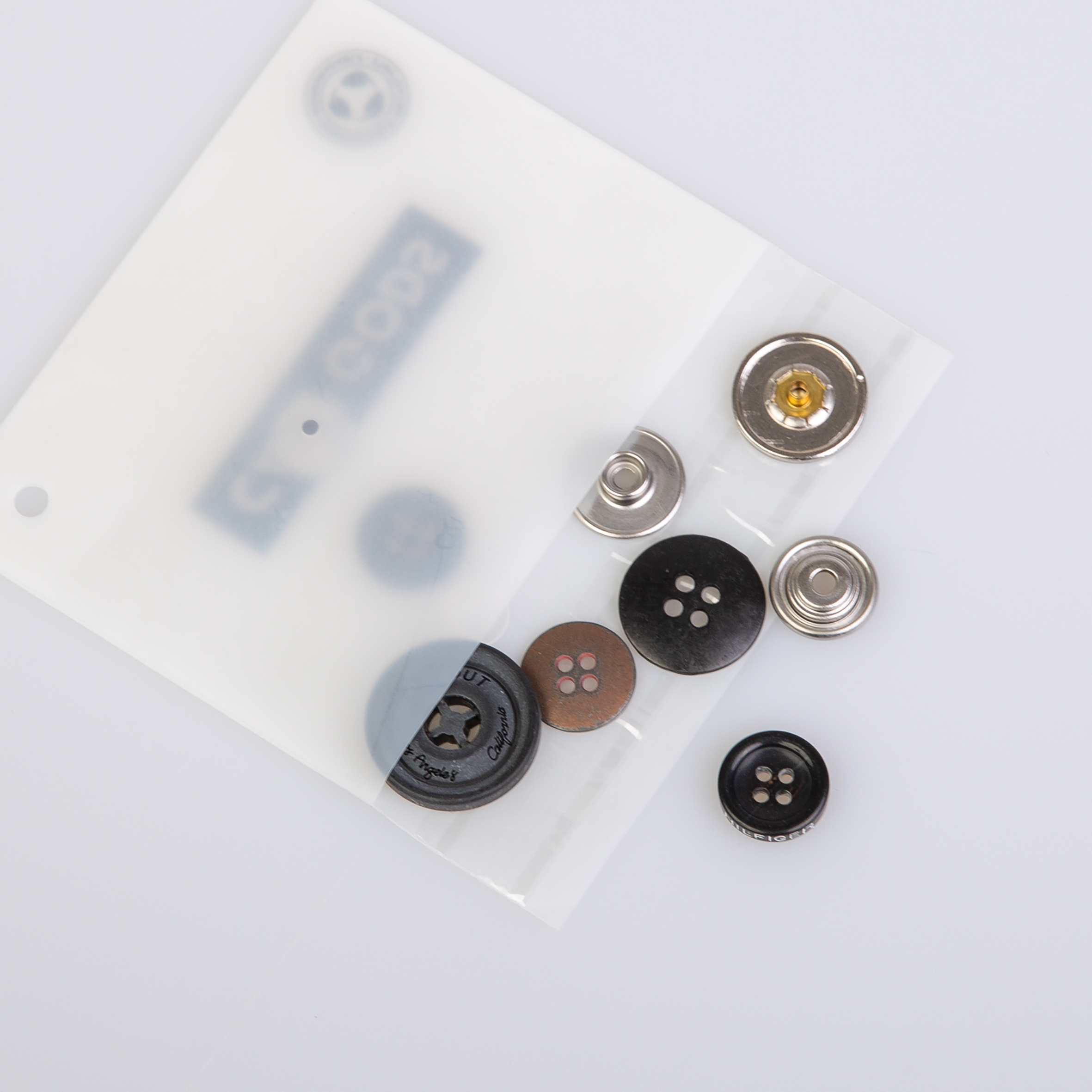

Our work

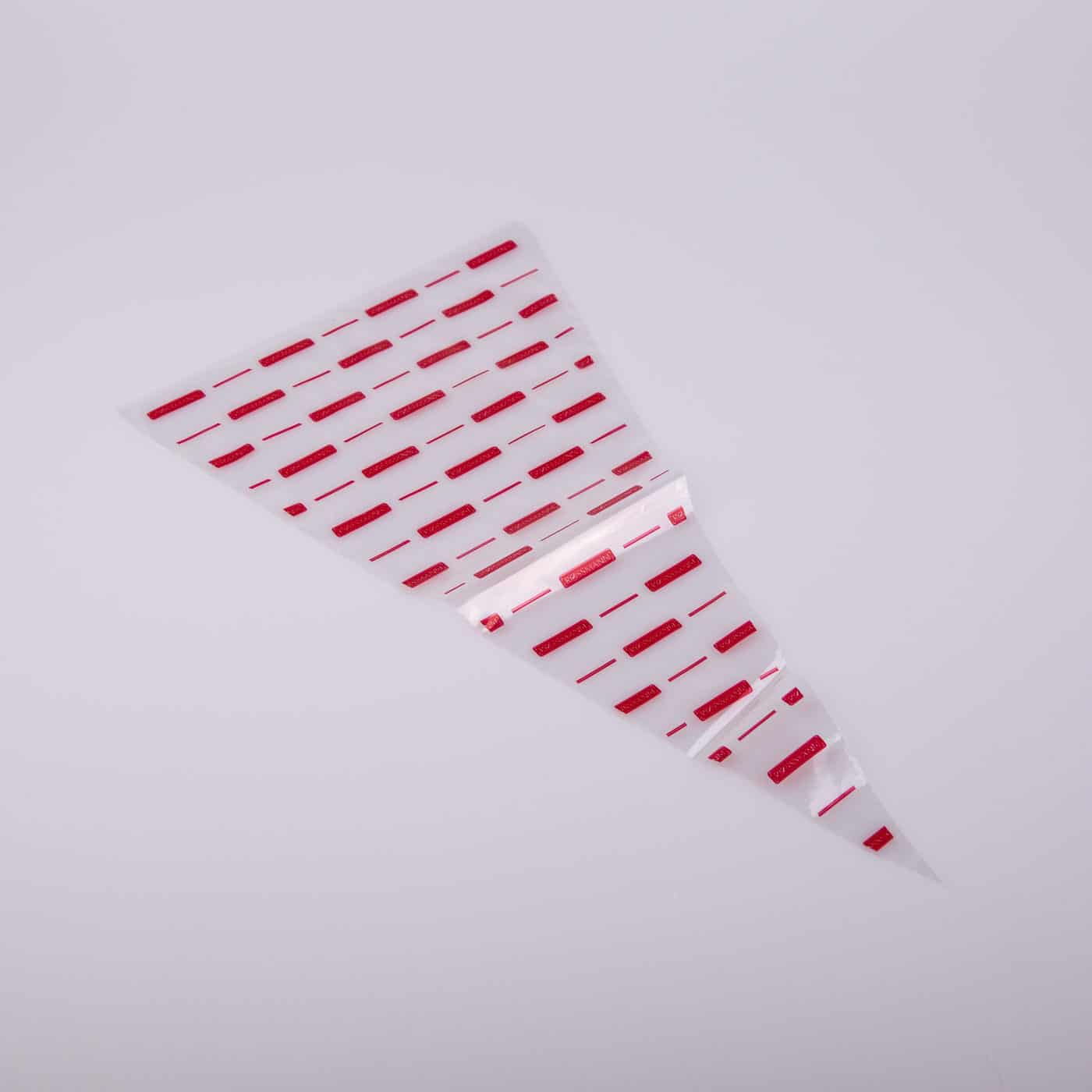

Bag with adhesive strip

Bag with adhesive flap

Bag with adhesive strip

LDPE bag

LDPE bag

BOPP bag

BOPP bag

LDPE closable bag

LDPE closable bag

BOPP bag

Bag with adhesive strip

Bag with adhesive strip

LDPE hockey card sack

Mail envelope with adhesive strip

Envelope with adhesive strip

Envelope with adhesive strip

LDPE bag with adhesive strip

Bag with handhole and adhesive strip

Zip-lock plastic LDPE bag

Doypack vhodný na tekuté výrobky

Doypack vhodný na tekuté výrobky

E-commerce courier bag

Sáček s plochým dnem

LDPE uzavíratelný doypack

Flat bottom pouch "bags"

Flat bottom pouch "bags"

Flat bottom pouch "bags"

Flat bottom pouch "bags"

Side gusset pouch

Big plastic bag

Envelope with adhesive strip

Are we what you are looking for?

We have a patent for bringing blue from the sky. Thanks to a strong, long-term position on the market, we have experience and technologies that can cover any requirements. We are a family business and we build our business on healthy values.

Why SALE

why SALE