Variables that affect price

LDPE plastic bags

Did you like the article?

Custom bags and other bespoke packaging are not priced “by gut feel.” The price of custom packaging is created by a combination of technical and process variables that have a direct impact on material, production, and the final functionality of the packaging.

Below is an overview of the main factors that have the greatest impact on the price of custom packaging. If any of them is missing in an inquiry, the quote necessarily becomes an estimate.

1) Packaging dimensions and construction

The basic parameter of every custom package. It’s not only about the external dimensions, but about what the package has to protect and how it will be handled during production, packing, and transport.

- internal product dimensions

- required allowance for seams, bottom, or padding

- type of construction (bottom, flap, zipper, lid, reinforcements)

The more complex the construction, the higher the demands on material, labor, and quality control. For shipping or rigid packaging, the construction often matters more than the print itself.

2) Packaging material

The material fundamentally affects the price and how the packaging behaves in practice. It’s not just about appearance, but about strength, durability, and suitability for a specific use.

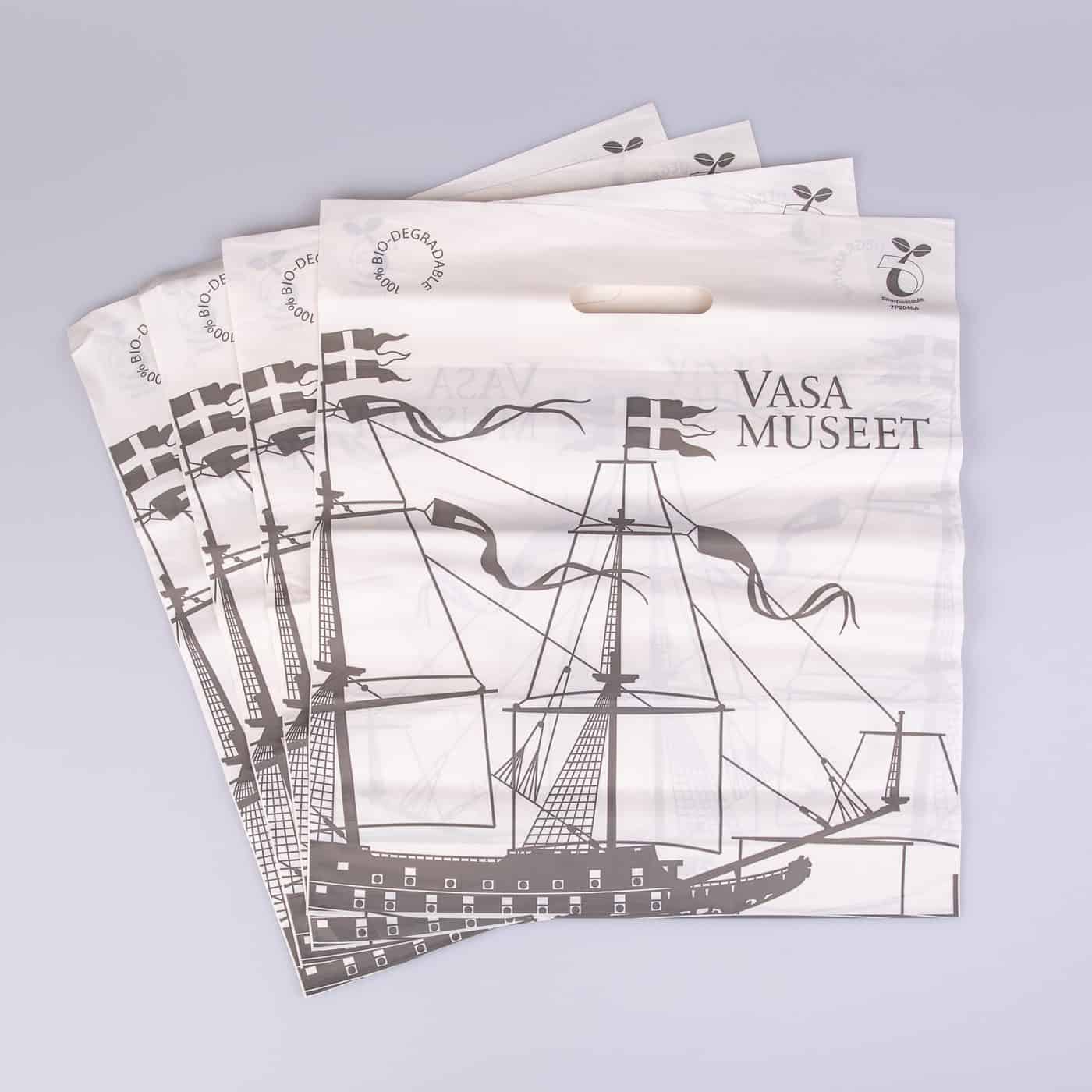

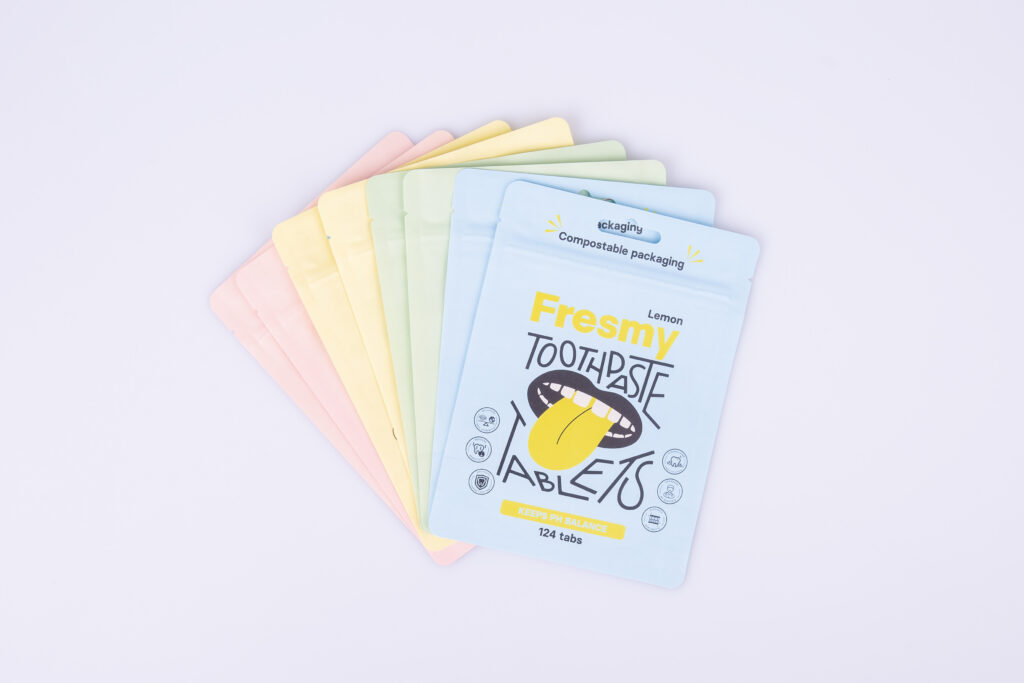

- material type (paper, plastic, textile, combinations)

- grammage or thickness

- material origin (raw or recycled)

- surface finish

3) Quantity and production runs

Quantity has a direct impact on the unit price of custom packaging.

Larger runs spread the setup costs of production; smaller runs are more expensive per piece, but offer greater flexibility.

4) Printing and packaging graphics

Printing is not just about design. It has a direct impact on production technology, time requirements, and the final price of the packaging.

- number of package sides with print

- size of the printed area

- color complexity of the artwork

- requirements for registration accuracy

5) Surface finishes and packaging details

Details that increase the visual impression and value of the packaging also increase its price.

- lamination or varnish

- embossing vs debossing

- special handles, zippers, or reinforcements

- combination of multiple materials

With premium packaging, these elements often decide whether the packaging feels ordinary or representative.

6) Packaging use

The price differs for single-use packaging versus packaging that is meant to withstand repeated use or logistics transport.

- single-use

- repeated use

- transport in the logistics chain

- direct contact with the product

Use determines the requirements for material, construction, and quality control.

7) Delivery deadline and production organization

Time pressure increases the price mainly because it limits production optimization options and increases transport requirements.

- reshuffling production capacity

- limited room for design adjustments

- higher demands on production organization

- higher transport costs

The earlier you submit the order, the more you can save.

What to include in an inquiry so the price is accurate

If you want to receive a quote, you need to provide basic technical information. You can find out what information we need to know in our article Packaging brief: the fastest way to an accurate quote

Considering your packaging? Get in touch before the final decision.

FAQ

There is no single universal answer, because the price depends on dimensions, material, quantity, and printing. But there is almost always one rule: the simpler the packaging and the larger the quantity, the cheaper it is. The lowest price usually comes from a simple construction, 1–2 color printing, no lamination and special finishes, and larger runs (to spread the production setup costs).

MOQ depends mainly on the type of packaging, material, and printing technology. On our website you can find the MOQ listed for each product category. If the MOQ is too high for you, write to us — we can often propose an alternative or come up with a solution that makes sense even for a smaller run.

In practice, it’s always a combination of all four factors. But two tend to have the biggest impact: quantity (because it significantly changes the price per piece) and printing complexity (number of colors, number of printed sides, and requirements for registration accuracy). Size and material are key mainly for rigid or shipping packaging, where construction and strength often cost more than the artwork itself.